With digital transformation, robotics in manufacturing has revolutionized the way in which industries function, resulting in unprecedented effectivity, diminished errors, and enhanced productiveness. As robots develop into integral to manufacturing traces, performing duties as soon as solely the area of people, the shift in direction of automation inside Business 4.0 heralds a brand new period of commercial manufacturing. This transformation not solely paves the way in which for elevated productiveness but in addition, opposite to considerations, probably revitalizes manufacturing in developed international locations with out considerably impacting structural unemployment.

The combination of 3D printing in manufacturing alongside robotics represents a synergy that would additional redefine manufacturing paradigms. These applied sciences, central to the idea of Automation and Business 4.0, are shifting the trade in direction of extra custom-made, versatile manufacturing processes. As companies navigate this transition, platforms like Shoplogix are instrumental in optimizing robotic operations, suggesting a future the place automation and human ingenuity coalesce to satisfy the calls for of contemporary manufacturing. This text will discover how robotics and 3D printing are reworking the panorama of commercial manufacturing, spotlighting challenges, alternatives, and future developments.

The Evolution of Manufacturing with Robotics

The journey of robotics in manufacturing has been marked by important milestones, every paving the way in which for the following leap in industrial innovation. From the inception of the primary industrial robotic within the Nineteen Fifties, a two-ton machine developed by George Devol, to the arrival of collaborative robots (cobots) designed to work alongside people, the evolution has been each fast and transformative.

Key Milestones in Robotics Evolution:

- Nineteen Fifties-Sixties: Introduction of the primary industrial robotic, Unimate, resulting in robots getting used for heavy lifting on meeting traces.

- Seventies: Shift in direction of supplies dealing with and precision work with smaller, electrical robots that includes superior controls.

- Nineteen Eighties: Incorporation of superior sensors and machine imaginative and prescient methods, introducing the Delta robotic recognized for its pace and precision.

- 2000s-Current: Developments in software program, significantly AI and machine studying, improve robots’ decision-making capabilities. Growth of cobots and autonomous cellular robots for elevated flexibility and security in materials dealing with.

This development of robotics in manufacturing underscores a shift from easy mechanical duties to complicated, precision-oriented operations facilitated by developments in expertise akin to mushy robotics, end-of-arm tooling, and the mixing of AI. The synergy between robotics and 3D printing, exemplified by Boston Dynamics’ use of 3D printing in creating elements for his or her robots, illustrates a future the place manufacturing isn’t solely about effectivity but in addition innovation and customization. As we glance in direction of 2030, the expectation is for robotics to develop into much more ingrained in our every day lives and work, pushed by the continual evolution of AI and the Web of Issues (IoT), marking a brand new chapter within the industrial revolution.

The Rise of 3D Printing in Manufacturing

The transformative influence of 3D printing in manufacturing can’t be overstated, providing a spectrum of benefits from accessibility to scalability. With printers accessible for underneath $800, the expertise is not only for hobbyists however has scaled to satisfy the calls for of mass prototyping and manufacturing. Regardless of its intensive utility throughout industries like aerospace, automotive, and medical, 3D printing faces limitations. For easy components in massive portions, conventional strategies like injection molding should still maintain the financial higher hand.

- Financial and Industrial Impression:

- Income Progress: The 3D printing trade boasted a income of $10.6 billion in 2021, with projections suggesting a leap to over $50 billion by 2030.

- Manufacturing Evolution: Main producers are more and more adopting 3D printing for mass manufacturing, necessitating developments in throughput and integration for widespread adoption.

- Innovation and Challenges:

- Technological Developments: Corporations akin to HP and GE are on the forefront, enhancing metallic binder jetting speeds to rival conventional metallic 3D printing strategies.

- Software program Options: Startups are innovating with Manufacturing Execution Programs (MES) software program, tailor-made for additive manufacturing to streamline the order-to-fabrication workflow via integration with current PLM, ERP, and IT software program, leveraging AI and machine studying.

- High quality Management Hurdles: The distinctive nature of every printed half presents important high quality management challenges, being addressed via new CT scanning methods and predictive software program developed by firms like ANSYS and Hexagon.

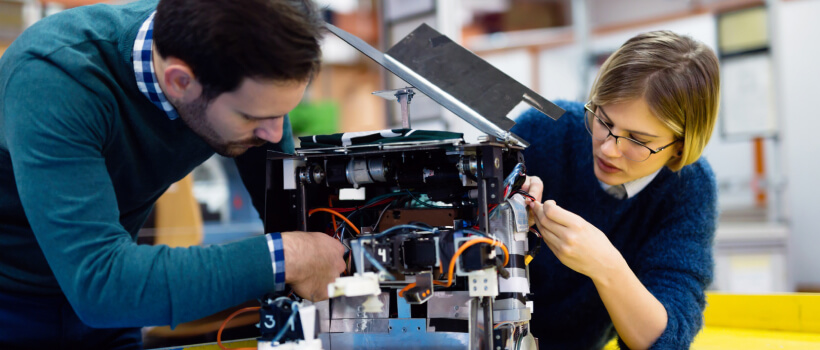

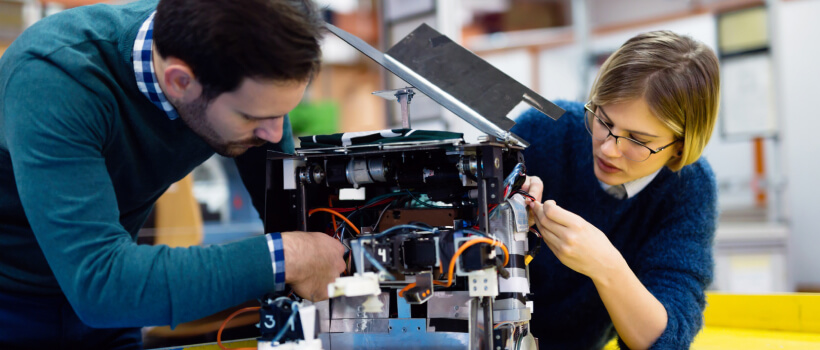

Synergizing Robotics with 3D Printing

Because the frontier of commercial innovation expands, the intertwining of robotics and 3D printing brings a brand new period of producing characterised by enhanced customization, effectivity, and performance. This synergy isn’t merely a technological development however a transformative power reshaping manufacturing landscapes.

- Swarm Robotics and 3D Printing Integration:

- Groups of robots, working in unison, are actually able to translating intricate designs into tangible merchandise, using a various array of supplies. This collaboration signifies a leap in direction of subtle manufacturing ecosystems the place customization and effectivity are paramount.

- Customization and Effectivity:

- The convergence of robotics with 3D printing applied sciences allows a degree of product customization beforehand deemed unattainable. Robotics, via its precision and repeatability, enhances 3D printing’s versatility, permitting for the creation of elements tailor-made to particular necessities and ecologies. This partnership is exemplified in areas starting from prosthetics, completely contoured to the consumer’s physique, to the intricate designs of sentimental robots, made potential via superior 3D printing supplies.

- Operational Synergy:

- Collaborative robots (cobots) improve the 3D printing course of by automating duties akin to materials dealing with and post-production ending, embodying the precept of ‘lights out’ manufacturing. This operational synergy not solely boosts manufacturing effectivity but in addition ensures consistency and high quality, decreasing waste and labor prices. The function of robotics in automating repetitive 3D printing duties underscores a symbiotic relationship, fostering innovation whereas streamlining manufacturing workflows.

This fusion of robotics and 3D printing is crafting a future the place the boundaries of producing are frequently redefined, pushed by the pursuit of effectivity, customization, and innovation.

Challenges and Alternatives

Within the dynamic panorama of 3D printing and robotics in manufacturing, collaboration emerges as a cornerstone for innovation. The fusion of experience from various areas, facilitated by digital conferences, underscores the significance of seamless communication. Regardless of the benefits, challenges akin to time zone variations and cultural nuances necessitate sturdy methods for efficient collaboration. A streamlined Product Lifecycle Administration (PLM) system, built-in with AI and generative design, can considerably improve collaborative efforts, driving the pursuit of resource-efficient and revolutionary options.

- Ability and Data Necessities:

- The intricate nature of 3D printing calls for a excessive degree of experience. As companies scale, the necessity to recruit and prepare proficient personnel turns into paramount. This extends past operational know-how to incorporate design and upkeep capabilities, important for optimizing the manufacturing chain.

- Regulatory Hurdles: Significantly in sectors like healthcare, stringent rules pose important challenges. The potential for product inconsistencies with 3D printing necessitates rigorous course of verification and validation, making certain security and efficiency meet stringent requirements.

Incorporating robotics into manufacturing introduces its personal set of challenges and alternatives. The variation of recent applied sciences requires re-education of employees, whereas the monetary facets, together with materials prices and technological upkeep, demand cautious consideration. Robotics’ function in monitoring and optimizing the 3D printing course of via AI algorithms represents a promising avenue for addressing operational challenges, highlighting the symbiotic relationship between these two transformative applied sciences.

Future Traits and Predictions

Within the realm of future developments and predictions, the synergy between robotics and 3D printing is poised to usher in transformative adjustments throughout numerous sectors. The next factors underscore the anticipated developments and their implications:

- Bioprinting and Organ Printing:

- Revolutionizing drugs by addressing organ shortages and enhancing illness modeling, drug testing, and tissue engineering.

- Potential to construct self-learning 3D printers via the mixing with deep reinforcement studying and meta-learning, optimizing organ printing processes.

- 4D Printing and Sensible Supplies:

- Introduction of adaptive and responsive merchandise, from self-assembling buildings to wearable gadgets and mushy robotics, leveraging the capabilities of 4D printing and sensible supplies.

- Hybrid and Multimaterial Printing:

- Enabling the creation of complicated, multifunctional merchandise combining metals, ceramics, or composites to attain diverse properties and efficiency.

- Considerably broadens the scope for personalization and innovation in product design and performance.

The projected development of the worldwide 3D Printing Robots Market, estimated to succeed in USD 4.9 billion by 2026, displays the burgeoning integration of 3D printing in typical manufacturing spheres. This development isn’t solely indicative of the rising reliance on 3D printing for industrial functions but in addition highlights the shift in direction of smarter, digital manufacturing paradigms. As industries like vehicle, aerospace, and drugs more and more undertake 3D printing, the relevance of this expertise, alongside robotics, in manufacturing is ready to soar, marking a brand new period of effectivity and innovation.

Conclusion

Because the journey via the transformative function of robotics and 3D printing in manufacturing unfolds, it turns into evident that these applied sciences will not be merely instruments of effectivity however beacons of innovation, driving an industrial evolution in direction of larger customization, productiveness, and sustainability. The synthesis of robotics with 3D printing emerges as a strong catalyst for redefining manufacturing processes, enabling the creation of complicated, tailor-made options that had been as soon as regarded as past attain. This melding of capabilities underscores a future the place the manufacturing traces will not be simply automated however are clever, versatile, and seamlessly built-in with human creativity and ingenuity.

Trying ahead, the implications of such developments lengthen far past the manufacturing ground, promising to carry a couple of important influence on economies, job markets, and societal wants. The continual evolution of those applied sciences suggests a path in direction of an more and more digital, environment friendly, and personalised manufacturing panorama. Fostering additional analysis and innovation in these fields will probably be essential in overcoming present limitations and unlocking the complete potential of robotics and 3D printing in manufacturing, thereby propelling industries into a brand new period of operational excellence and product innovation.

FAQs

How is 3D printing utilized within the robotics trade?

3D printing serves as a key device for robotics producers, significantly for the manufacturing of customized components. Moreover, it’s instrumental in repairing robots by enabling the on-demand creation of substitute components and spares. These components could be reverse-engineered and enhanced to rectify points with current elements and designs.

What significance does 3D printing maintain in manufacturing?

Within the manufacturing sector, 3D printing performs a vital function by slashing prices and dramatically decreasing lead instances from weeks to mere hours, enhancing operational flexibility. It presents industrial producers with revolutionary strategies to refine manufacturing processes, develop novel enterprise fashions, and foster innovation.

What features do robots carry out in manufacturing?

Robotics in manufacturing is predominantly utilized for a wide range of duties. These duties could be categorized into three major teams: materials dealing with, processing operations, and meeting and inspection. Examples of fabric dealing with embrace transferring supplies and loading or unloading machines.

In what methods are robots reworking manufacturing?

Industrial robots are revolutionizing the manufacturing trade by considerably boosting productiveness. Able to working at speeds surpassing human capabilities and dealing repeatedly with out fatigue, robots can ship a considerable uptick in manufacturing output.

How can [x]dice LABS Assist?

[x]dice LABS’s groups of product homeowners and specialists have labored with world manufacturers akin to Panini, Mann+Hummel, tradeMONSTER, and others to ship over 950 profitable digital merchandise, ensuing within the creation of recent digital traces of income and completely new companies. With over 30 world product design and growth awards, [x]dice LABS has established itself amongst world enterprises’ prime digital transformation companions.

Why work with [x]dice LABS?

- Founder-led engineering groups:

Our co-founders and tech architects are deeply concerned in initiatives and are unafraid to get their fingers soiled.

- Deep technical management:

Our tech leaders have spent many years fixing complicated technical issues. Having them in your venture is like immediately plugging into 1000’s of person-hours of real-life expertise.

- Stringent induction and coaching:

We’re obsessive about crafting top-quality merchandise. We rent solely the perfect hands-on expertise. We prepare them like Navy Seals to satisfy our requirements of software program craftsmanship.

- Subsequent-gen processes and instruments:

Eye on the puck. We continuously analysis and keep up-to-speed with the perfect expertise has to supply.

Our CI/CD instruments guarantee strict high quality checks to make sure the code in your venture is top-notch.

Contact us to debate your digital innovation plans, and our specialists can be comfortable to schedule a free session.